Inventory & Machinery Tracking

Manage goods for sale, consumables, tools, and machinery effortlessly. Track lots, assignments, repairs, usage, and critical maintenance.

Oak's inventory management system handles everything from goods for sale to tools and machinery. Track inventory lots, assign equipment to workers or groups, record repairs, monitor usage patterns, and schedule critical maintenance.

Our comprehensive approach ensures you always know the status and location of every asset on your estate.

Inventory Categories

- Goods for Sale: Track harvested produce, processed goods, and other items intended for sale with lot numbers and quantities.

- Consumables: Manage fertilizers, pesticides, fuel, and other supplies with usage tracking and reorder alerts.

- Tools: Keep track of hand tools, small equipment, and implements assigned to workers or stored centrally.

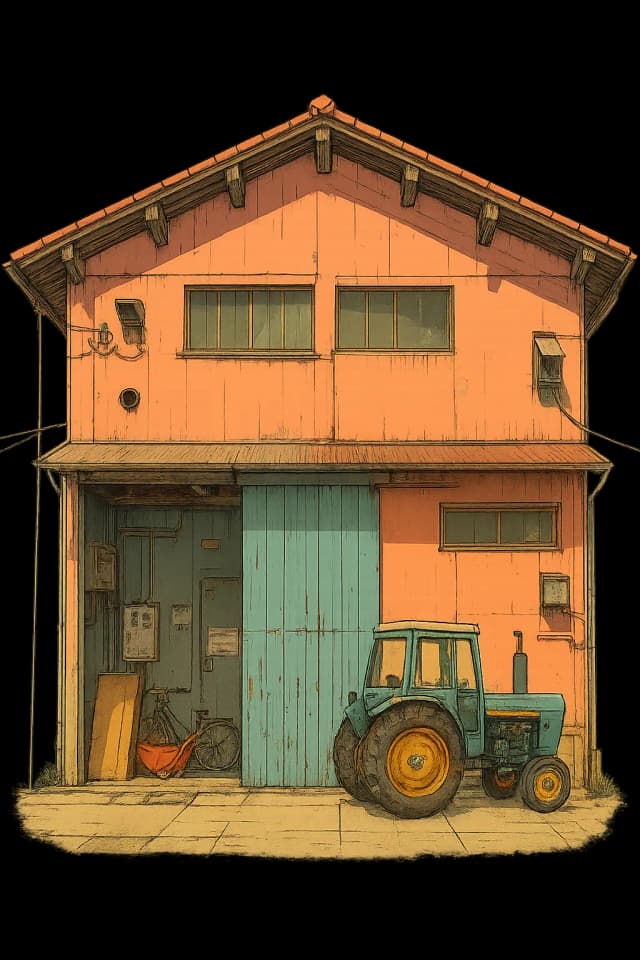

- Machinery: Manage tractors, sprayers, processing equipment, and other valuable machinery with detailed records.

Lot Management

- Lot Tracking: Create and track inventory lots with details like quantity, date received, supplier, and cost.

- FIFO/LIFO Support: Manage inventory movement with first-in-first-out or last-in-first-out tracking.

- Expiry Management: Track expiry dates for time-sensitive materials and get alerts before items expire.

Equipment Assignment

- Worker Assignment: Assign tools and equipment to individual workers with accountability tracking.

- Group Assignment: Allocate equipment to work groups or gangs for shared use.

- Location Tracking: Know where every piece of equipment is at any given time.

- Return Management: Track equipment returns and condition upon return.

Maintenance & Repairs

- Maintenance Schedules: Set up regular maintenance schedules for machinery and get reminders when service is due.

- Repair Records: Log all repairs with details on what was fixed, parts used, and costs incurred.

- Service History: Access complete service history for any piece of equipment.

- Downtime Tracking: Monitor equipment availability and understand downtime patterns.

Usage Tracking

- Consumption Reports: Track how consumables are used across activities, blocks, and time periods.

- Equipment Utilization: Monitor how frequently machinery is used and identify underutilized assets.

- Cost Allocation: Allocate inventory costs to specific activities or blocks for accurate expense tracking.

Integration with Operations

Inventory data integrates with attendance records to track which tools and materials were used during specific work sessions. This creates a complete picture of resource utilization and helps optimize both labor and material costs.